Advanced technology, for zero defects.

Leading edge equipment. HDT designs and builds manufacturing equipment with many proprietary features and innovative technologies. Our forty plus year experienced Automation and Tooling Center has developed innovations that replaced Hydraulic, oil-powered equipment with cleaner, more energy-efficient electric and pneumatic-powered technologies. This equipment runs much quieter and cooler (the energy needed to cool our factories has been reduced significantly), using 90 percent less energy than previous equipment.

Our innovative forming stations are then integrated into a highly automated process, to which we are fully committed, even in best-cost countries. This ensures consistent and reliable manufacturing in all HDT locations around the globe.

To our manufacturing process, we add “in-station” inspection systems – force monitoring, vision, laser and other sensors – to ensure the early detection, segregation, and isolation of any manufacturing anomalies.

Exceptional tooling made in-house.

Tooling is vitally important to the making of exceptional, high-quality parts. For decades, we've built proprietary tooling in-house, in our automation and tooling centers. Our apprenticeship program ensures a sustainable team of highly skilled toolmakers that designs and crafts the best tube-forming tooling in the world.

Leading-edge equipment using exceptional tooling is one of the main advantages of working with HDT versus other suppliers.

Cost efficient.

Exceptional quality. Repeatable. Reliable. Durable. Adaptable. The result? Our products exceed customer expectations, provide exceptional value, and earn the appreciation of the vehicle manufacturing purchasing teams with whom we work.

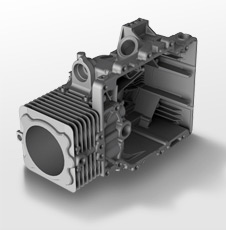

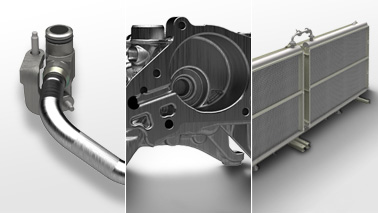

PRODUCTS

Everything we make is engineered, and manufactured to exceed customer expectations.

LEARN MORE

ADVANTAGES

See what we do better than our competitors that results in great value for our customers.

LEGACY

A number of companies with rich histories combine to form HDT, a true global leader.