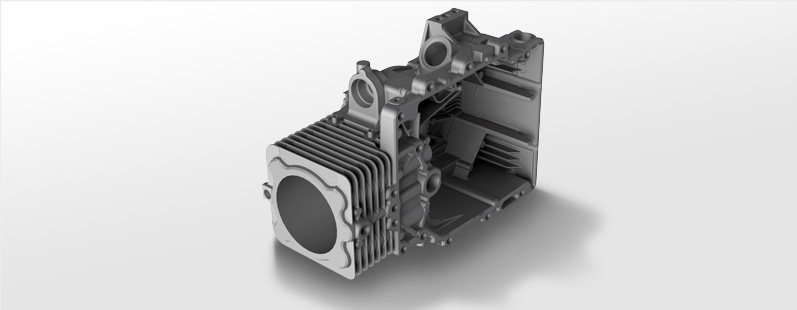

High-pressure Die Casting Technologies

- From decades of experience in aluminum die casting and machining, we produce complex geometry with exceptionally high levels of porosity and surface finish

- Our process, from melting to finishing, is monitored for maximum time- and cost-efficiency

- Fully automated cells ensure high yield and a robust process

- Parts-washing cells ensure a high level of cleanliness and adhesion characteristics

- With six melting ovens and four crucibles, we can utilize customer-specific alloys during product development stage and serial production

- Our in-house radiology equipment allows us to perform product CT scans

Technologies we use:

- High-pressure die casting

- Horizontal milling machine

- Sand blasting

- Washing

Experienced professionals, high-quality parts, highly competitive prices

Our people know what they’re doing. We can set the injection curve of a specific die quickly – with adequate brake and closure force and lubrication – to match both cosmetic and structural characteristics and preserve the die for maximum usage. Issues are identified and resolved quickly and efficiently.

Why do we use that technology? Because the design of the dies’ ingate system includes thermoregulation and internal/external movements.

HIGH PRESSURE DIE CASTINGS

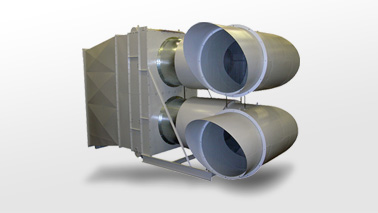

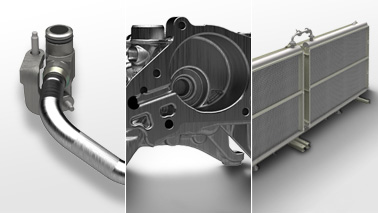

Our die castings and assemblies perfectly fit fuel, electric, and hybrid applications.

PRODUCTS

Everything we make is engineered, and manufactured to exceed customer expectations.