Thermal and vehicle systems

- Many HDT products contain assemblies that are designed, validated and manufactured in house that help maintain optimal fluid temperatures and pressures. These devices decrease fuel consumption and increase reliability.

- Full design and product validation center

- In-vehicle position vibration validation ensures parts that will last the entire vehicle lifecycle

- Coupled Hose Validation

- We use environmental chambers, vibration equipment, cyclic humidity booths and other destructive and non-destructive testing to ensure the reliability of our coupled joints at all temperature & motion ranges specified

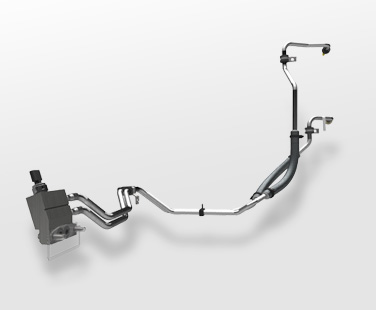

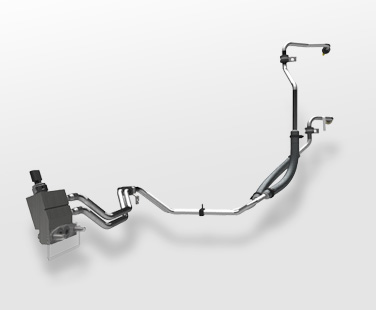

Transmission Fluid Cooling Assemblies

Ours are the most durable, lightweight and dependable transmission fluid handling solutions available today.

Engine Oil Cooling Assemblies

We help keep the lifeblood of the engine cool under the most demanding conditions.

Vehicle Systems – Coolant Assemblies

New vehicle technologies require coolant to be conducted for various vehicle systems including battery thermal management

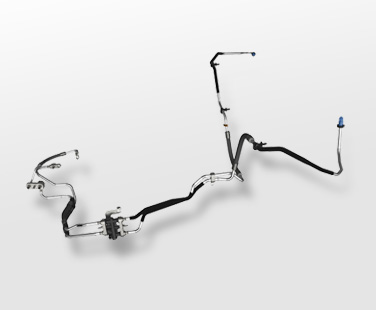

Vehicle Systems – Low Pressure Power Steering Lines

Engineered and designed for maximum results and extreme dependability

Thermal Management Valve Assemblies

Designed to optimize fluid temperatures to maximize fuel efficiency and reduce emissions.

Pressure Management Valve Assemblies

To avoid the challenges inherent in normal and demanding vehicle operations.

Wire Wound (Brush) Heat Exchangers

Lightweight aluminum heat exchangers that incorporate innovate “wire fin” technology.

FLUID HANDLING TECHNOLOGIES

We design solutions for internal combustion, hybrid and battery electric vehicles.

ADVANTAGES

See what we do better than our competitors that results in great value for our customers.

TECHNOLOGIES

The goal of our technological insights? Zero defects and 100% satisfied customers for the entire product lifecycle.