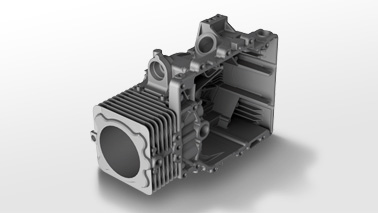

High-Pressure Die Castings

HDT produces precise, lightweight high-pressure die castings and assemblies for various fuel, electric and hybrid applications.

Powertrain

- Coolant pump housings

- Transmission and engine oil pump housings

- Crankcase covers

- Clutch plate covers

Chassis

- Steering system housings

- Printed circuit board covers and housings for vehicle control and safety products

- Structural supports

- Brushless motor carriers

- Gas valve housings

- Each day at our vertically integrated, state-of-the-art casting factory in Italy, we manufacture thousands of high-volume, lightweight, precise castings. In-house CT scans are used to verify our products and processes

- Our process reduces porosity, meeting the most stringent industry standards. We also design our process for maximum die life to reduce program lifecycle costs

- We preserve the tightest, most stringent geometric tolerances

- The shapes of HDT casting products are highly complex. We never shy away from the most challenging, demanding product designs

- Many HDT casting products feature value-added mechanisms, from a production process designed to be mistake-free

DIE CASTING TECHNOLOGIES

With decades of aluminum die-casting and machining, we are one of the world’s best at manufacturing precise and lightweight components.

ADVANTAGES

See what we do better than our competitors that results in great value for our customers.

TECHNOLOGIES

The goal of our technological insights? Zero defects and 100% satisfied customers for the entire product lifecycle.