Industrial Heat Exchanger Technologies

Our proprietary modeling software allows us to design systems that meet precise customer requirements quickly and cost-efficiently.

These significant software systems – fully designed and developed by HDT – can be installed at any site, anywhere in the world.

- Our stringent contamination standard ensures dedicated flushing devices equipped with particle counters and double filtering systems

- Every unit meets project standards for climate (i.e., winterized solutions) and performance (pressure and temperature)

- Full compliance with API, ASME, PED and CUTR codes requirements as well as major O&G standards (Shell dep, Aramco, PDO)

- NDT is available to identify potential material defect (dye penetrant, carbon content, UT, X-ray, PMI)

- All processes are done in-house, from design to paint; only a short lead time is required, and track building is expedient

Technologies we use:

- Plasma cutting

- Folding

- Welding

- Sand-blasting

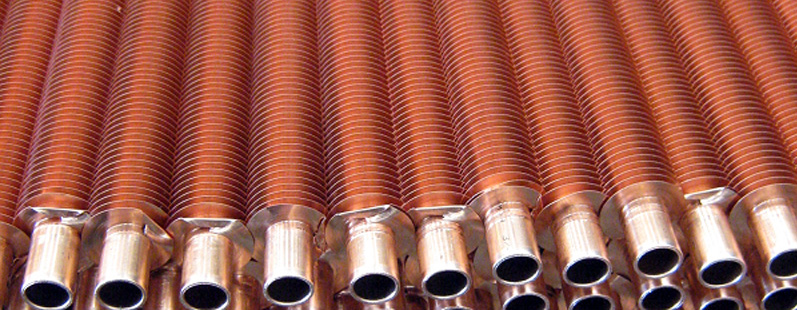

- Wire-winding

- Painting

- Flushing

Why are these technologies important?

Our wire-winding has been patented and we are the only manufacturer using aluminum wire-wound coolers. Our particular strengths are in design and our in-house software, which accurately predicts the thermal performance of our heat exchangers; and in testing, in which all thermal modes are validated in our R&D lab, which features a state-of-the-art wind tunnel.

Our bonded turbulators enhance the heat rejection rates of our exchangers to ensure a minimal footprint for a given duty.

The result? Designs tailored specifically to a customer’s exacting requirements, with reduced material usage and lower prices.

HIGH PRESSURE DIE CASTINGS

Our die castings and assemblies perfectly fit fuel, electric, and hybrid applications.

FLUID HANDLING SYSTEMS

Our systems are for internal combustion, hybrid and electric vehicles.

PRODUCTS

Everything we make is engineered, and manufactured to exceed customer expectations.